|

Oil Leaks and Spills

|

|

Why is it material?

Managing the risk of spills is directly linked to the safe, socially and environmentally responsible operation of all our facilities.

Our main activities, including oil refining, storage and transport, involve the risk of spills due to unforeseen operational malfunctions or accidents, and most of them are land based and adjacent to the aquatic environment - sea.

All precautionary and risk reducing measures are in place to manage the risk of spills, to provide environmental protection and maintain the company’s sustainability.

|

Our approach

At all operational stages, we identify and manage all possible risks in order to mitigate them on time and minimize the consequences of unforeseen operational incidents and accidents.

We apply rigorous risk management and control measures, which are evaluated regularly for continuous improvement according to best internationally recognized practices.

During the transport of crude oil and other products, the Marine Pollution Contingency Plan is strictly enforced in all port facilities (in coordination with the Local and National Pollution Response Plan), by organized personnel teams and use of appropriate technical equipment and materials. Regular preparedness drills are conducted in cooperation with all stakeholders.

Maritime and inland safety standards for transport of products by trucks and tankers are adhered to through ongoing controls, including compliance with international regulations and treaties such as the International MARPOL Convention on the Prevention of Pollution from Ships.

During the refineries’ production process, in accordance with the approved Environmental Terms of Operation (AEPO), there is a system for continuous monitoring of the subsoil and groundwater to prevent their pollution from potential hydrocarbon leakage.

In addition to the above, soil leakage response drills are conducted based on possible scenarios in accordance with relevant procedures and with all available resources and support for optimal management.

|

|

Our ambition

We are committed to continuously reinforcing prevention measures along with directly and effectively responding to potential spills.

Our goal is zero spills on the ground and water in which we operate. In the event of an unavoidable leakage, our goal is immediate response and remediation.

|

|

Sustainable Development Goals (SDGs)

|

|

Performance – quantitative data

The Group was among the first worldwide to adopt the new process safety indicators according to CONCAWE guidelines and in full alignment with API RP 754, 2016 (Recommended Practice 754, "Process Safety Performance Indicators for the Refining and Petrochemical Industries"), including those related to leaks and spills at all its industrial facilities.

More specifically, all relevant indicators related to unplanned or uncontrolled leaks of any material, including non-toxic and non-flammable materials (i.e. steam, hot condensate, nitrogen or other inert gases, compressed CO2 or compressed air) are monitored.

As previously described, all monitored leaks are not associated with environmental impacts, with the exception of those related to hazardous substances that were not adequately addressed by measures to prevent contact with the ground or water.

Process safety events based on CONCAWE definitions

|

Installation

|

HELPE (AIC, EIC, TIC)

|

ΕΚΟ

|

ΟΚΤΑ

|

|

Process Safety Event (PSΕ-1)

|

5

|

0

|

0

|

|

Process Safety Event (PSΕ-2)

|

8

|

0

|

1

|

|

Total Process Safety Events (PSΕ)

|

13

|

0

|

1

|

|

Process Safety Event Rate (PSΕR)

|

1.41

|

0

|

1.33

|

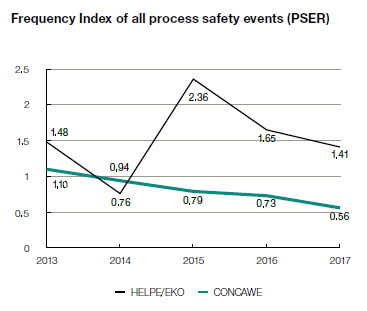

The following diagram shows the fluctuation of the Total Process Safety Event Rate (PSER), which corresponds to the total number of process safety events per one million man-hours compared to the equivalent CONCAWE indicator.

The indicator shows a significant decrease to the magnitude of 15% in 2017 compared to the previous year. To reduce these indicators, an annual target to minimize process safety events is set in all installations with the ultimate goal of achieving zero incidents.

Prevention - confinement - remediation actions

The Group applies rigorous procedures and emergency response plans to address pollution in the event of an oil spill.

Preparedness and response drills are regularly carried out at all facilities for the event of a ground or marine spill in cooperation with the competent authorities.

Specifically:

- At our three refineries, we continuously monitor the subsoil and groundwater to control and prevent pollution in the event of hydrocarbon leakage or spill, in addition to strictly enforcing Marine Pollution Conservation Procedures for spill incidents during product and raw material loading and unloading at port facilities.

Especially in the case of oil spills at sea, it should be noted that response strategy for each incident is determined in cooperation with the competent authorities (port authority, associated Ministry) and actions and preventive measures taken during each incident are in accordance with the provisions of the Local Pollution Prevention Plan.

Means and equipment used in order to handle spills include booms, oil skimmers, dispersants and other absorbent or adsorbent materials.

- HELPE's marine fleet has Emergency Plans to avoid pollution from oil spills in accordance to MARPOL Regulation 73/78, setting out the required actions to stop or mitigate impacts in the event of an oil spill caused by an accident during operations, or as a result of a serious incident such as a collision or explosion.

- In fuel storage facilities, leaks are handled through Emergency Plans that address all leak events that may occur at tank dikes, pumping stations, truck loading stations, pipelines, etc.

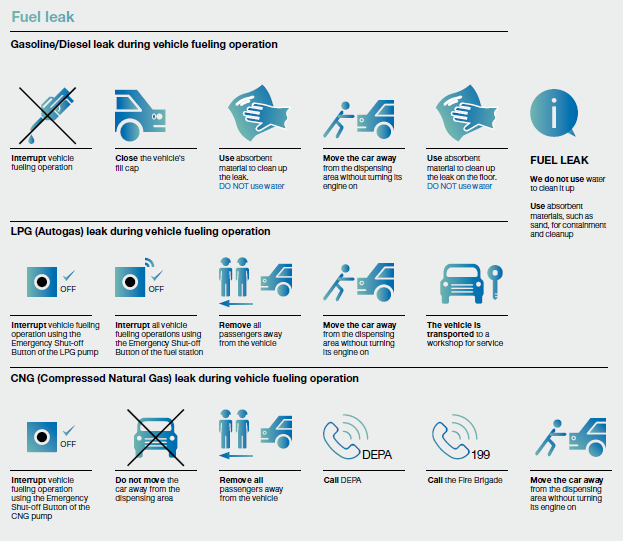

- At EKO's petrol stations, strict rules are in place to manage any leak that could occur during the customer vehicle refueling process, which in this case is associated with safety hazards rather than environmental impact. Indicatively, safety rules cover gas and petrol leaks as well as LPG or natural gas.

Next steps

Baseline reports showing the current status of soil and groundwater at the industrial refinery facilities in accordance with the Industrial Emissions Directive (IED 2010/75 / EU).