|

Waste and Circular Economy

|

|

Why is it material?

The sustainable and optimal use of materials and natural resources throughout their life cycle is an important business opportunity and mirrors our commitment to environmental protection.

Petroleum products - by-products that are characterized as waste (produced by our Group or by third parties) at a certain stage of their life cycle, constitute a major opportunity for us when reused as raw material in our production facilities or recovered to be used by third parties as a fuel according to our business approach towards circular economy.

Constantly reducing the amount of waste for final disposal contributes significantly not only to minimize impact on the environment and to human health, but also toward substantially reducing our operating costs.

|

Our approach

We adopt and implement circular economy principles in the design and implementation phases of our investment strategy through best practices and technologies across our product lifecycle, such as:

- reuse of water with the aim of reducing fresh water consumption and wastewater production.

- reduction of solid waste for landfill through investments in modern waste treatment plants and through synergies for further use by third parties, such as energy use of refinery oily waste by third parties or other waste as additives in their products.

- developing synergies toward the recovery of waste for energy and / or raw materials within the Group’s numerous activities, such as the re-refining of wastewater from fuel storage facilities.

By applying Best Available Techniques to the production process and operating innovative waste treatment processes, we continue to recover significant amounts of oily waste at our refineries, while steadily reducing waste and minimizing what cannot be of further use.

|

|

Our ambition

Our priority is to continuously increase the utilization rate throughout the life cycle of the materials and natural resources by recycling and re-using them in our production process, as well as by developing broader synergies for their use.

Our goal is to significantly reduce waste to final disposal – landfill (up to 15% by 2030).

|

|

Sustainable Development Goals (SDGs)

|

|

Performance – quantitative data

Regarding wastewater and solid waste management, the overall effort to reduce waste production and maximize recycling continued in 2017 for feasible waste streams. For remaining waste streams, the best possible on-site waste management practice with regard to the environment and human health was applied.

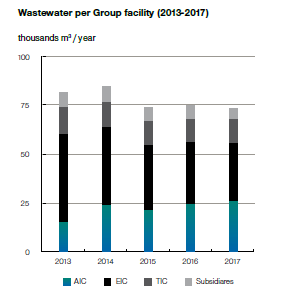

Advanced waste treatment facilities, such as the Group’s 3-stage wastewater treatment units, ensure the continuous improvement of our performance as presented in detail in the diagrams below that show the comparison of the amounts of produced wastewater and solid waste sent for final treatment the last five years respectively. Specifically, and according to the declining trend of the last five years, produced wastewater reduction continued in 2017 from the Group’s total activities.

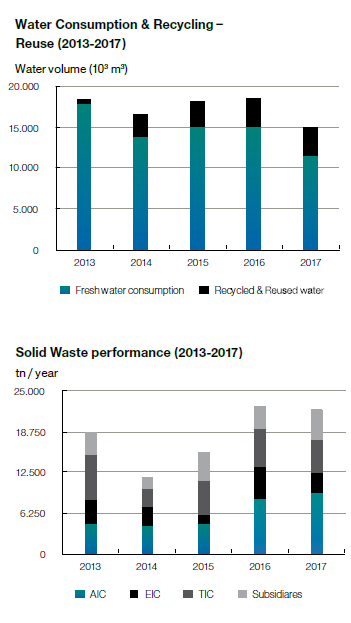

The reduction of produced effluents is directly related to the use of water and increased re-use/recycling of water. As shown in the diagram below, water consumption continued to decline in 2017 while recycling and re-use percentages remained at high levels.

In 2017, total water consumption decreased 17.5% from the previous year, while recycling and reuse percentages remained high (24%) as presented in the diagram below.

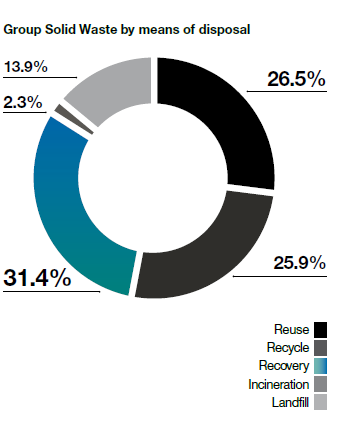

Regarding solid waste, 2017 presented a reduction in the total quantity produced in relation to the previous year. It is worth mentioning that the largest percentage of solid waste quantities come from cleaning product tanks, and therefore these amounts may vary significantly every year depending on programmed tank maintenance and secondly on the solid waste treatment unit’s availability (either on or off the facility).

The diagram below presents the various waste treatment and disposal methods used to manage the produced solid waste in 2017. As evidenced, over 80% of the total waste is either re-used, recycled or used further through a raw material recovery process.

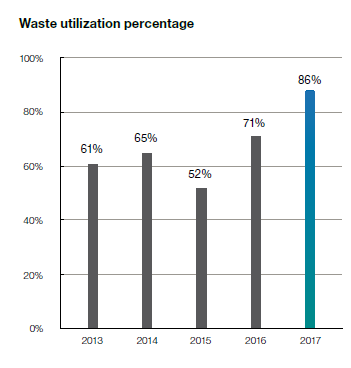

It should be highlighted that the utilization rate (re-use, recycling, recovery, energy recovery) of waste generated (compared to that led to final landfill) shows an increasing trend the last 5 years, with the ultimate goal of stabilizing at more than 85%, as depicted in the diagram. In addition, efforts continue in order to recycle as many waste streams as possible, including paper, plastic, small or industrial-sized batteries, fluorescent lamps, electronic equipment, aluminum, etc., with active employee participation in all the Group's facilities and offices.

Especially for petroleum refinery sector, the percentage of oil waste recovered and returned to the production process as a raw material for re-refining is also monitored. These quantities of waste come both from the production process and from third parties. The table below shows the recovery quantities and percentages from the three Group refineries, while it is worth noting that over the past five years, approximately 570,000 tonnes of oily waste have been re-refined.

Recovered Raw Materials – 2017

|

Installation

|

Percentage Recovered

|

Quantity (tonnes)

|

|

Elefsina Refinery

|

1.27%

|

68,304

|

|

Thessaloniki Refinery

|

0.65%

|

29,761

|

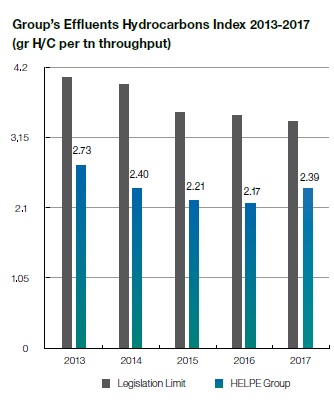

In addition to quantitative data, the treated effluents’ quality characteristics are monitored by the hydrocarbon per throughput index in the refinery sector. In 2017, the hydrocarbon index average for the Group’s three refineries remained 30% below the statutory limit. Indicatively, the diagram below presents the Group’s effluent hydrocarbon index for the past 5 years in relation to the legislation’s threshold.

Next steps

Actions have been initiated to further improve performance with regard to the monitored quantitative and qualitative indicators as well as in compliance to the Industrial Emissions Directive (IED) and to the new limits according to the Conclusions of Best Available Techniques for Petroleum Refining (REF BAT Conclusions Decision).